In 1912 Adorna Albanesi opened her restaurant in Campofilone, here she cooks and sells her Maccheroncini of Campofilone egg to the inhabitants and visitors of the town.

In 1912 Adorna Albanesi opened her restaurant in Campofilone, here she cooks and sells her Maccheroncini of Campofilone egg to the inhabitants and visitors of the town.

In the 60s his nephew Nazzareno turns his grandmother’s vision into reality by enlarging the laboratory (as seen in photos). Today we are back to the origin of pasta: the raw material.

Every harvest is different, our work as farmers is to get the best possible from what nature gives. This means there is no perfect recipe for our semolina. But we respect the soil resting cycles, pay great attention to fertilisation, prefer organic and continue to choose grains that are resistant and genuine species. From the summer harvest, hard grains are matured in silos, chilled to avoid mould and impurities. This helps us to get a semolina that is always supremely important for a great pasta. With this unique way of working we can crystallise the wheat starch molecule for a perfectly digestible pasta.

We raise about 6,000 hens, not so many compared to a medium-sized facility. They grow up in units of 800 hens, living on the ground, in a ventilated and dry place, because they are sentient beings, not just egg machines. In keeping with the life cycles, we feed them with cereals from our chain to get the very high quality eggs that are used in making La Campofilone egg pasta. Their feed is designed to be balanced to their nutritional needs: Noble cereals such as maize and barley, for intense and fragrant yellows, clean vegetable fats that condense fat and minerals giving the calcium needed for a healthy shell. Campofilone pasta is an intense and delicate yellow colour, like our amazing eggs.

The first word to describe the handicraft is: slowness.

'The time it needs' is our production motto.

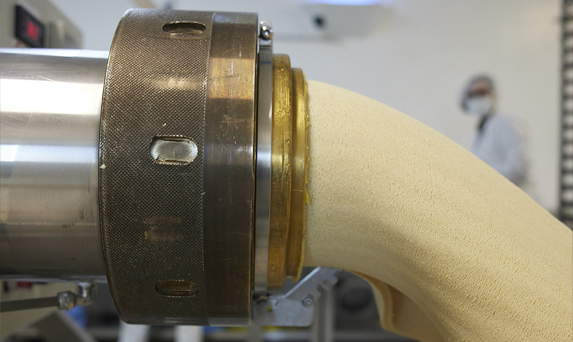

Our raw materials are processed within the company with a traditional method at a controlled temperature that never exceeds 36° and the pasta is dried for 24 hours, or 48 for some types.

After years of industrial pasta we seem to have forgotten that true pasta is not a heavy dish, it is enjoyable but also a nutritious food that is absorbed slowly. Our pasta is light, easy to digest and excellent nutrition with a scientifically guaranteed low glycemic index.

HOME

COMPANY

PASTA

OUR CHAIN

NEWS

CONTACT

La Campofilone s.r.l.

società

agricola

Località Ficiarà, 27

63828 CAMPOFILONE

(FM)

Tel +39 0734 931294

Fax +39 0734 937354

lacampofilone@lacampofilone.it

lacampofilone@lacampofilone.com